Powder Metallurgy is a highly efficient metal-forming process that creates precision components by heating compacted metal powders. It is favored for its material efficiency, net-shape capability, and cost-effectiveness in high-volume production.

The automotive sector is the largest consumer of PM parts. As vehicles shift toward greater fuel efficiency and lightweight designs, PM technology is essential for producing complex, high-performance components.

Key Applications

Engine timing sprockets, oil pump gears, transmission synchronizer rings, shock absorber components, and ABS sensor rings.

Advantages

Creates components with unique wear-resistant properties and reduces vehicle weight without compromising structural integrity.

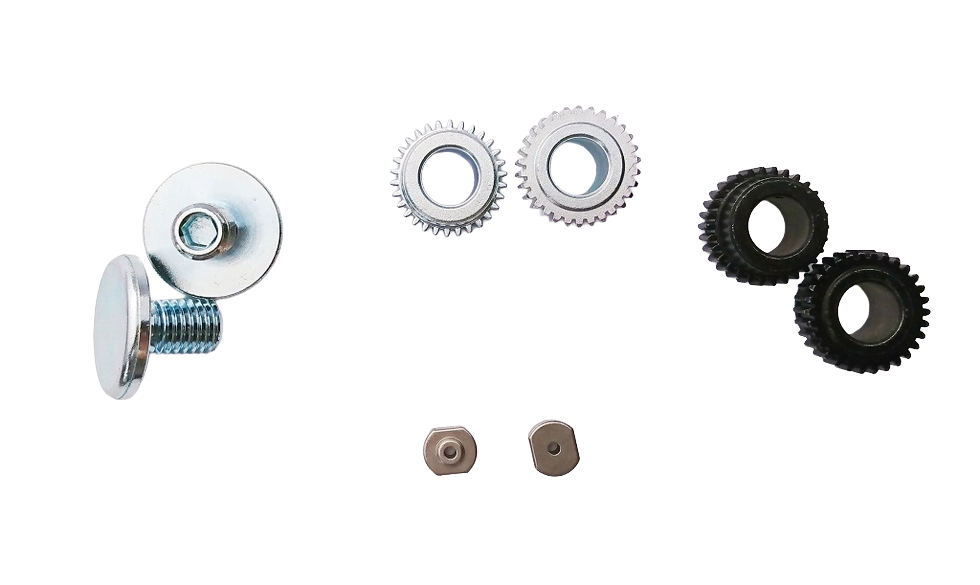

For general industrial machinery, PM is the preferred choice for structural parts that require high precision and durability while avoiding the high scrap rates of traditional machining.

Key Applications

Spur and helical gears, self-lubricating bearings (oil-impregnated), bushings, couplings, and flanges.

Advantages

The ability to produce "self-lubricating" parts significantly reduces maintenance needs and noise in industrial environments.

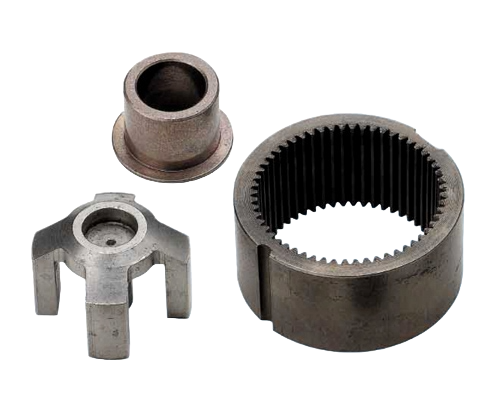

Power tools demand components that are compact, high-torque, and impact-resistant. PM technology is ideal for the intricate internal drive systems of these handheld devices.

Key Applications

Planetary gear systems, impact blocks, drill chuck components, and gearboxes.

Advantages

Provides excellent dimensional consistency and high fatigue strength to withstand the repetitive stress of professional-grade tools.

In the fast-paced world of consumer electronics, parts are becoming smaller and more aesthetically demanding. PM and MIM provide the precision needed for modern gadgets.

Key Applications

Smartphone hinge mechanisms (for foldable phones), wearable device frames, fiber optic connectors, and smart lock internal components.

Advantages

Capable of processing hard materials like stainless steel and tungsten with superior surface finishes and extremely tight tolerances.

High-efficiency magnetic parts and structural components for electric vehicles and renewable energy systems.

Key Applications

EV motor cores, wind turbine gears, solar tracker components, and high-efficiency magnetic couplings.

Advantages

Supports the transition to clean energy with materials optimized for magnetic performance and durability.

Biocompatible, high-precision stainless steel parts for surgical instruments and medical robotics.

Key Applications

Surgical staplers, laparoscopic jaws, dental implant tools, and drug delivery system components.

Advantages

MIM technology allows for the mass production of complex, sterile-grade stainless steel instruments.

Wear-resistant gears, bushings, and cams designed for heavy-duty industrial automation equipment.

Key Applications

Conveyor system gears, hydraulic pump parts, textile machinery components, and heavy-duty bushings.

Advantages

Offers superior wear resistance and load-bearing capacity for continuous industrial operations.

Complex net-shape lock cylinders, latches, and security components produced with high security standards.

Key Applications

High-security lock cylinders, deadbolt latches, padlock bodies, and electronic lock gears.

Advantages

Net-shape manufacturing prevents tampering vulnerabilities and ensures consistent precision for security mechanisms.

Summary

Powder Metallurgy is no longer just a cost-saving alternative; it is a primary design solution for modern engineering. Whether it is the durability required for an engine or the micro-precision needed for a smartphone hinge, PM provides a versatile and sustainable manufacturing path.